Luxembourg, 14 June 2023 – As part of its decarbonisation process, ArcelorMittal Luxembourg has confirmed its plan to invest in a new electric arc furnace (EAF) at its Belval site.

This investment is part of a series of projects that were the subject of a memorandum of understanding (MoU) signed last September between ArcelorMittal Luxembourg and the Ministry of the Economy. This MoU confirms the willingness of the Luxembourg government to financially support this type of strategic investment, through the various applicable aid mechanisms. For this project in particular, the subsidies made available by the Luxembourg State amount to approximately 15 million euros.

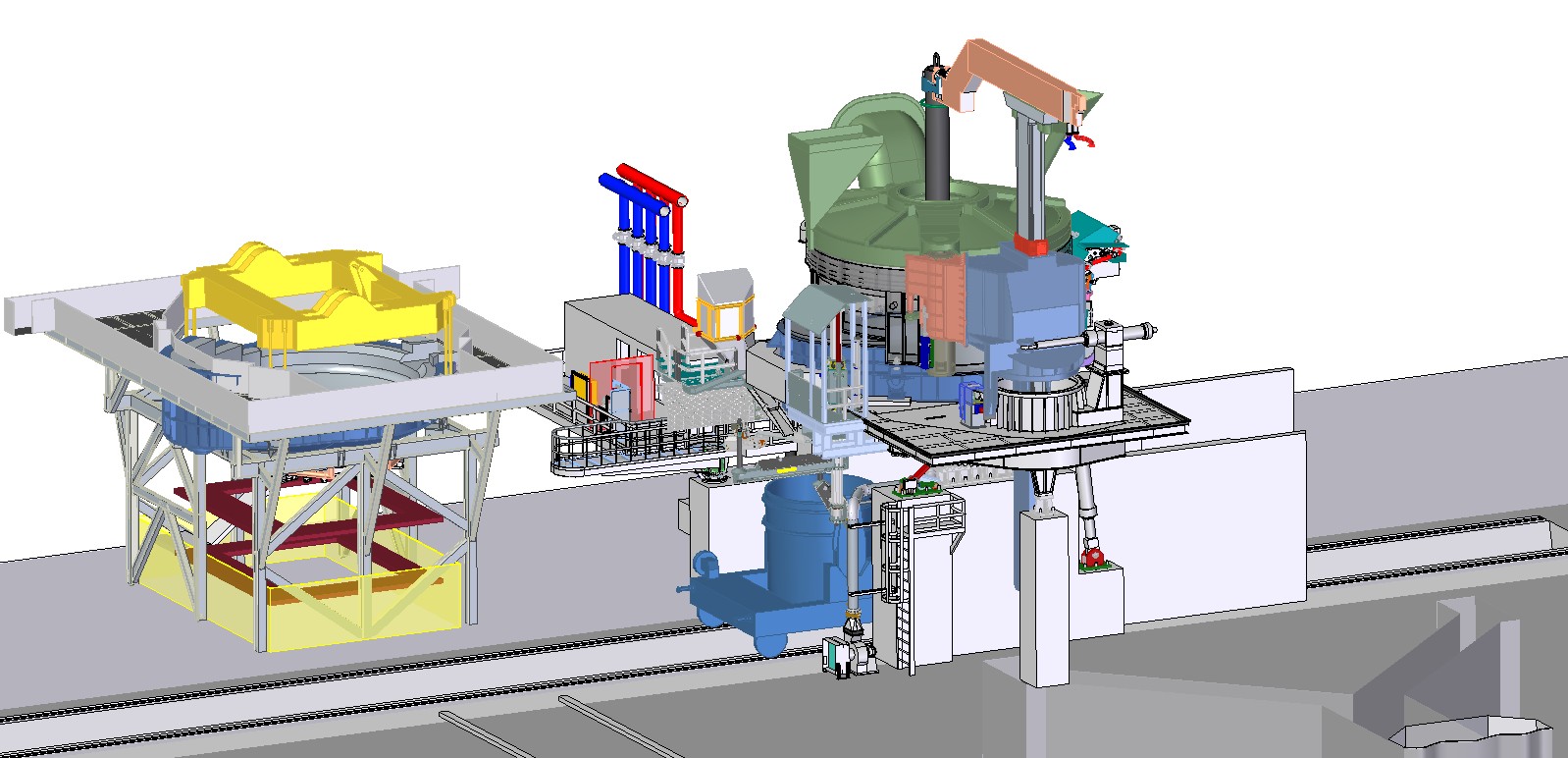

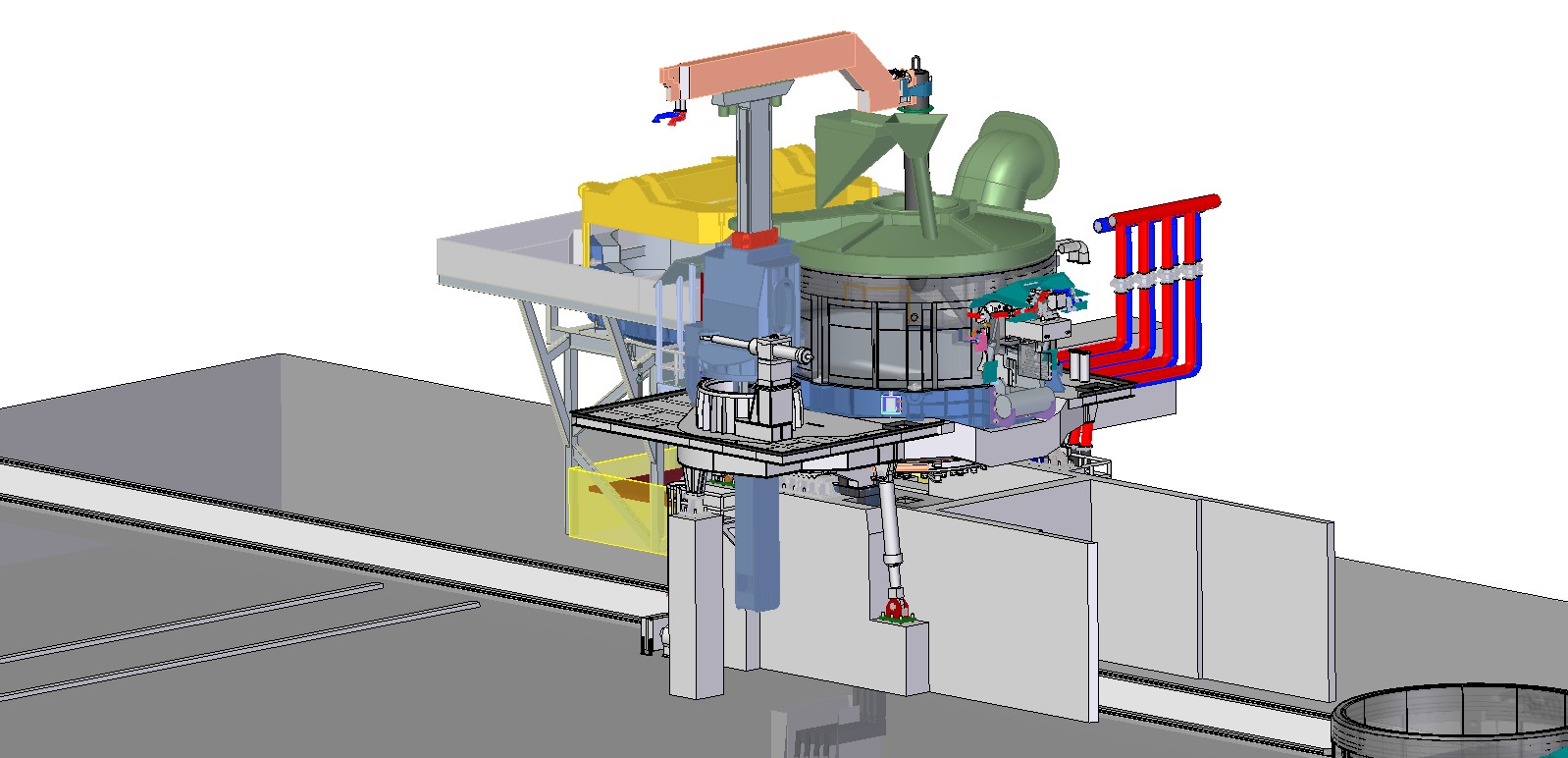

The new Belval electric arc furnace is one of the flagship projects of this Memorandum of Understanding. It will offer improved energy efficiency and an increase in steel production capacity in Luxembourg of almost 15%, reaching 2.5 million tonnes of steel per year. With this new facility replacing the current EAF operated since 1997, and with additional investments to be made in other areas of the Belval steel plant, ArcelorMittal Luxembourg plants will be self-sufficient in crude steel production capacity to cover the needs of finished rolled products in the Grand Duchy. In particular, the Mill A at the ArcelorMittal Rodange site will henceforth be supplied exclusively by this new installation, for the production of its numerous ranges of rails and niche products.

Electric furnaces produce steel from recycled scrap and can be operated using solely renewable energy. In addition to the advantages of recycling scrap, this process reduces CO2 emissions by a factor of six(1) compared with conventional steel production using blast furnaces. The installation of the new electric furnace in Belval will start this year, with commissioning in 2025.

Mr Geert van Poelvoorde, CEO ArcelorMittal Europe, said: “This project is the first concrete expression of the memorandum of understanding that we signed last September, together with Minister of the Economy Mr. Fayot, to develop initiatives aimed at enabling ArcelorMittal’s Luxembourg sites to embark on the road to carbon-neutral steel production. This is a major step forward in a project that has progressed quickly and demonstrates the Luxembourg government’s support for our decarbonisation strategy”.

Mr Sanjay Samaddar, CEO ArcelorMittal Europe Long Products, said: “Thanks to the support of the Government, we can make this progress in the modernisation of our installations, to improve our operational energy efficiency and to make progress in reducing our carbon footprint. It is also an illustration of the ArcelorMittal Group’s desire to invest in the future of the Luxembourg steel industry, which has unique know-how in high value-added products.”

Mr Pierre Jacobs, CEO of ArcelorMittal Luxembourg Long Products, said: “It is excellent news that we are now able to proceed with building a new electric arc furnace for Belval; this project will benefit all of our steelmaking operations in Luxembourg. It will be a challenge for our teams to have this facility operating by 2025 but I am confident that with our know-how and the motivation of our teams, we will be able to meet this challenge successfully.”

Mr. F. Fayot, Minister of Economy, declared “The realisation of this project is tangible proof that we are capable, in Luxembourg, of sustaining and developing our industry, through a project that fits perfectly into the roadmap set by Europe to combat climate change, and is also in line with the work begun by the High Committee for Industry.”

(1) One ton of steel produced by the traditional route using blast furnaces generates about 2.2 tons of CO2. The same ton of steel made from recycled scrap melted in an electric arc

furnace emits only 600 kg of CO2. This figure drops to 300 kg when the electric furnace is operated with renewable energy. As an example, a sheet pile produced by this process has a CO2 balance of 370kg/ton.

About ArcelorMittal

Luxembourg

ArcelorMittal has its global headquarters in Luxembourg. At the national level, the group has 8 sites throughout the country, including the administrative centers in Luxembourg City and Esch-sur-Alzette, various steel production units for long and wire products as well as distribution and steel service centers. ArcelorMittal also runs a R&D Centre in Esch-sur-Alzette.

ArcelorMittal Luxembourg is a leading producer of long products, such as steel beams and sheet piles, which are sources of innovation in the modern construction sector. Heavy Jumbo sections and high-performance steel grades from ArcelorMittal in Differdange have a worldwide reputation for use in high-rise buildings and allow a reduction in weight (and thus CO2 emissions) of up to 40%. The high quality and reliability of ArcelorMittal Belval’s steel sheet piles have made them the benchmark in this market.

Specialized in the production of rails of various profiles, ArcelorMittal Rodange offers the world’s widest range of rails for overhead cranes and a selection of rails for tramways made of ultra-resistant steels, as well as the world’s largest angle irons, widely used for the construction of electric pylons to transport energy over long distances.

Finally, ArcelorMittal Bissen operates in three market segments: wire for fencing and agriculture (vineyard wire), industrial wire (wire for gabions, cable reinforcement) and metal fibers for reinforcing concrete for floors, tunnels and prefabricated buildings.

For more information on ArcelorMittal in Luxembourg, please visit: http://luxembourg.arcelormittal.com and follow us on Twitter @ArcelorMittal_L and Instagram @arcelormittalluxembourg

Worldwide presence

ArcelorMittal is the world’s leading steel and mining company, with a presence in 60 countries and primary steelmaking facilities in 16 countries. In 2022, ArcelorMittal had revenues of $79.8 billion and crude steel production of 59.0 million metric tonnes, while iron ore production reached 45.3 million metric tonnes.

Our purpose is to produce ever smarter steels that have a positive benefit for people and planet. Steels made using innovative processes which use less energy, emit significantly less carbon and reduce costs. Steels that are cleaner, stronger and reusable. Steels for electric vehicles and renewable energy infrastructure that will support societies as they transform through this century.

With steel at our core, our inventive people and an entrepreneurial culture at heart, we will support the world in making that change. This is what we believe it takes to be the steel company of the future.

ArcelorMittal is listed on the stock exchanges of New York (MT), Amsterdam (MT), Paris (MT), Luxembourg (MT) and on the Spanish stock exchanges of Barcelona, Bilbao, Madrid and Valencia (MTS).

For more information about ArcelorMittal please visit: http://corporate.arcelormittal.com/